Bottle and Jar Boxes

-

Portavasetti Jar Carriers with Windows, Avana

As low as $74.48SKU: 54V-5553-IT-PORAVA-configMore Sizes Available...

- Options Avaliable to Hold 2 and 3 Jars

- Natural Eflute Texture

- Color/ Finish: Kraft

-

Portavasetti Jar Carriers with Windows, Nero

As low as $174.38SKU: 54V-5553-IT-PORNER-configMore Sizes Available...

- Options Available to Hold 2 and 3 Jars

- Matte Black Linen Texture

- Color/ Finish: Black

- 100 per case

-

Seta Nero Window Boxes, 60ml Olive Oil Boxes w/insert

As low as $85.78SKU: 54V-5553-IT-OBNER-configMore Sizes Available...

- Black Linen Embossed Texture

- PLA Biodegradable Windows

- Options for 4 and 6 bottles

- Color/ Finish: Black

- 50 per case

-

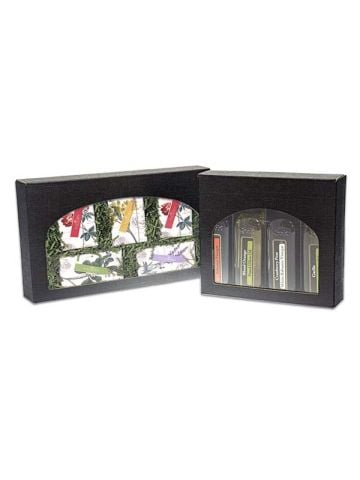

Seta Nero Window Boxes, Box w/ Arched Window

As low as $85.78SKU: 54V-5553-IT-WBNER-configMore Sizes Available...

- Black Linen Embossed Texture

- PLA Biodegradable Windows

- Color/ Finish: Black

- 50 per case

-

Natural Kraft Olive Oil/Vinegar Bottle Carrier

As low as $62.78SKU: 54V-5553-IT-OCNAT-configMore Sizes Available...

- Smooth Finish

- Avaliable in Tall, Grende and Bottle Sizes

- Color/ Finish: Natural Kraft

-

Seta Nero Olive Oil/Vinegar Bottle Carrier

As low as $46.28SKU: 54V-5553-IT-OCNER-cofig- Black Linen Finish

- Avaliable in Tall, Grende and Bottle Sizes

- Color/ Finish: Black

-

Sage Groove Olive Oil/Vinegar Bottle Carrier

As low as $78.58SKU: 54V-5553-IT-OCSAG-configMore Sizes Available...

- Sage Grooved Finish

- Avaliable in Tall and Grende Sizes

- Color/ Finish: Sage

-

"Textured Rib" Olive Oil / Vinegar Bottle Boxes, Avana

As low as $62.28SKU: 54V-5553-IT-OBAVA-configMore Sizes Available...

- Kraft Textured Rib Finish

- Avaliable in Tall and Grende Sizes

- Color/ Finish: Kraft

- 50 Per case

-

Open Style Bottle Carriers

As low as $40.78SKU: 54V-5553-IT-BT-configMore Colors and Sizes Available...

- Corrugated Material

- Heavy Construction

- Holds 375 ml or 12 oz Bottles

- Color/ Finish: Black

- 30 per case

Bottle & Jar Boxes

These italian boxes and carriers are a simple, yet elegant way to showcase and protect your products in jars and bottles from Olive Oil, Jams, Salsa, Sauces, Spices and even more. Boxes and carriers are wholesale priced for small businesses. Perfect for wine shops, gourmet food shops, restaurants, farmers markets and gift/candy shops. Made in Italy.

Portavasetti Italian Carriers

Available in Nero, Matte Black Linen and Avana, Naural Eflute Texture. These jar carriers come in a variety of sizes rainging short 4-3/8" H jars to tall 8-3/8"H jars. Carriers also vary on being able to hold 2 to 3 jars. Carriers ship flat and pop open by pushing in the corners and flating the inside bottom to lock into place. The windows then fold inward to be used as dividers between the jars so they do not collide directly and help keep the jars in place. Easy handle for travel. 50-100 per case depending on size

Custom options include; screen printing (only on the Nero finish) and 4-color process print.

Seta Nero Window Boxes

Available only in Nero, black linen embossed color. These boxes come with PLA Windows. Boxes are available in two sizes 6" x 5-3/8" x 1-3/8" and 9" x 5-3/8" x 1-3/8", which holds 4 bottles and 6 bottles respectively. You can purchase them with or without the insert that creates dividers to go in between each of the bottles. 50 per case.

What is PLA?

PLA, or polylactic acid, is produced from any fermentable sugar. Most PLA is made from corn because corn is one of the cheapest and most available sugars globally. This is used to create a clear like material, similar to plastic in food packaging. PLA products achieve international standards for biodegradation, naturally degrading rather than piling up in landfills. It does require certain conditions to degrade quickly. In an industrial composting facility, it can break down in 45–90 days. PLA requires 65% less energy to produce than traditional, petroleum-based plastics. It also emits 68% fewer greenhouse gases.

Italian Bottle Boxes & Carriers

Available in "Seta Nero" (Black Linen Finish), Natural Smooth Kraft, and Sage Groove. These bottle carriers come in a variety of sizes ranging from Tall Carrier (200 ml), Grande Carrier (375 ml or 12 oz) to Bottle Carrier (750 ml). Carriers also vary on being able to hold 2 to 3 bottles. Carriers ship flat and pop open by pushing in the corners and flating the inside bottom to lock into place. The windows then fold inward to be used as dividers between the bottles so they do not collide directly and help keep the bottles in place. Perfect sizes for oil and vinergar bottles as well as beer and sauces. Easy handle for travel. 30-50 per case depending on size.

Custom options include; screen printing and 4-color process print.

Bottle Boxes

Available only in "Texture Rib" finish. These bottle boxes come in a variety of sizes ranging from Tall Boxes (200 ml) to Grande Carrier (375 ml or 12 oz). Boxes also vary on being able to hold 2 to 3 bottles. 50 per case.

Open Style Kraft Bottle Carriers

Available in Smooth Black Kraft Finish with Black Interior and Smooth Natural Kraft Finish. These carriers come in two sizes 5-1/8" x 5-1/8" x 11-3/8" and 7-5/8" x 5-1/8" x 11-3/8". Carriers also vary on being able to hold 4 to 6 bottles. 30 per case.

Custom options include; screen printing and 4-color process print.

Custom Options

These carriers and boxes can be customized by screen printing and 4-color process print.

Screen Printing

In this method a screen is used instead of a plate. Ink is pushed through a fine mesh screen to transfer the desired image to the product. It is our most versatile process because of its gentle and precise nature. We can match any PMS ink color when printed on a white substrate. When ordering a colored substrate, please be aware that the background will affect the end result and change the color. Therefore, we suggest you request an ink draw down to assure the color meets your customer’s expectations. Multiple colors can be accomplished on a wide variety of products. We use UV ink which creates a glossy finish. A matte additive can be requested to remove the gloss; or a metallic powder can be added to the ink to create a brushed metallic look. Screens must be made on every order, repeat or new, as the screen is reclaimed and used again. The film used to make the screens is stored in the file to be used on future orders.

Choose screen print when...

- When your artwork covers a large area. Excessive foil raises the price so Screen Printing is cost effective for these situations.

- Use varying percentages of ink to create a print that looks like multiple colors.

- Discounts for multiple colors. Sizes combine when using the same artwork.

- We mix our own ink which means you get the color you want!

- Large coverage in hot stamping means trapped air and broken foil. Screen printing is the solution.

- Our tightest printing option at 1/16” shift between colors.

Process Printing

Four color process printing is a system where a color image is separated into four different color values: Cyan, Magenta, Yellow and Black (CMYK). By using just these four colors, most of the spectrum or gamut of colors are reproduced, with a total of over 16,000 different color combinations!

When the artwork has been split up into these four color channels, the amount of density for each is also calculated. The artwork is then printed in a pattern of small dots based on these various densities to create the look of a solid color(s). Process printing makes it possible to print anything from a simple 1 color logo to a full spectrum photographic image. The possibilities are endless.

Process print, although more expensive than other printing options, can be a better option in some cases for your packaging solution.

Good candidates for process printing include:

- Logos containing several colors with tight registration.

- Artwork containing photographic images.

- Printing on textured substrates, such as E-Flute.

- Short-run jobs since plate/screens are not required.

Process printing also has no shift tolerance between colors. So, you can be sure to have your logo printing where and how you want it.

Validate your login