Artwork Guidelines

Submitting Artwork

Please upload your art file on the order page where indicated or email your sales representative with the file attached. Please make sure to add all pertinent information such as company name, contact info and order number (if possible) on the email.

The order pages artwork upload allows for the following file types: .png, .jpg, .jpeg, .ai, .webp, .eps, and .pdf. If your file type is not listed, it may need to be converted to a compatible format. If you need assistance converting graphics, reach out to a sales rep directly, or contact [email protected].

The plate creation requires vector art. Vector art is different from other common image formats because it is infinitely scalable. Unlike raster images, which are composed from pixels, vector images identify the edges of shapes using equations, this means that their sharpness won't diminish when scaled up. If you are unsure on your artwork's quality, reach out to a sales representative, we are here to help. If you are unable to provide vector art, additional art charges will occur. Charges will vary based on the art provided.

We also recomend that if the custom job will be printed in one-color, to provide us with one-color artwork. If you are unable to provide one color art additional art charges will occur. Charges will vary based on the art provided.

All fonts must be converted to outlines/curves/paths. Be sure to send all and printer fonts. DO NOT send PC fonts - we are not able to use them. If your file contains PC fonts it is necessary for you to convert to outlines/curves/paths before emailing us your file. If fonts are not properly sent delays on your job can occur.

If you want your artwork edited with additional text added please also provide your sales representative with the font name for our art department to get the closest match to the existing artwork.

What is Vector Art?

The best and highest quality imprints are made from vector art.

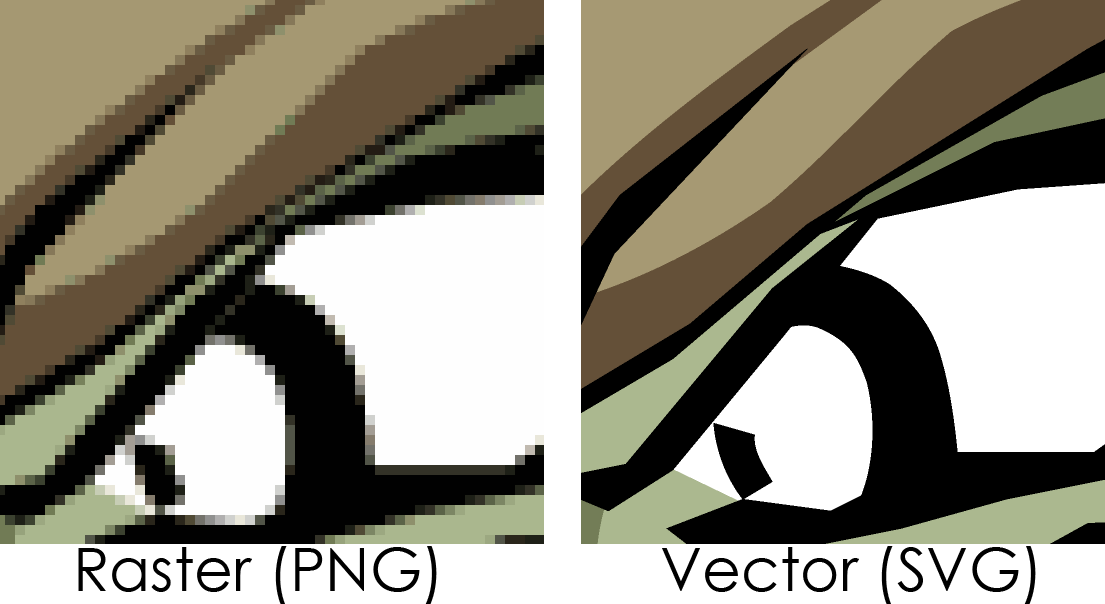

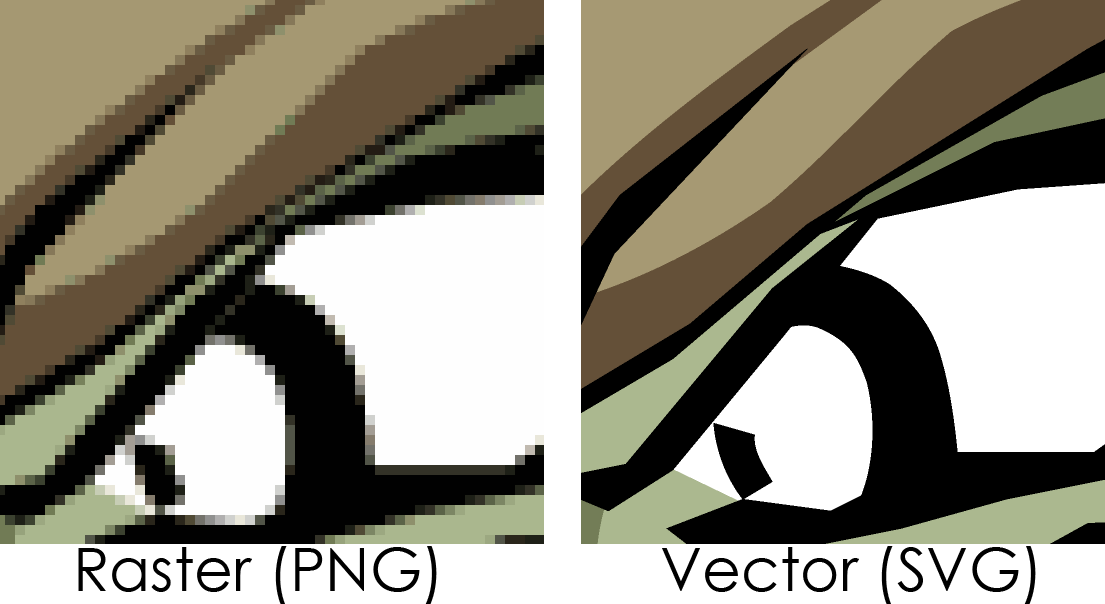

VECTOR ART is made up of paths, defined by points, lines and curves, specified by mathematical equations. Vector art can be scaled to any size and retain its proportions, and sharpness with no loss in quality. Note: A scanned image (e.g. .jpg, .gif, .bmp, .tiff, .psd, .pdf) or art created in a photo/ paint program is not vector art, it is a raster image.

RASTER IMAGES are a collection of pixels or dots arranged in a rectangular grid known as a bitmat. Scaling up a raster image results in a loss of quality as the pixel squares get bigger and create jaggy edges on the image. In addition, placing, linking, embedding, or copying these images into a drawing program does not convert them into vector art and it will not meet our art requirements.

Vector V2. Bitmap

Vector will retain its integrity when the size is modified. The bitmap loses its quality when enlarged because each individual pixel is increased.

Artwork Location and Size

When creating your custom bags it is important to know that within our imprint location you logo size can vary and so can it's placement. Our default is to have the logo scaled to the largest it can be in the imprint location and centered in the imprint area. If you are interested in a placement other than center or size that's not the largest for the imprint location, be sure to note it when placing your order. We are confined to the imprint size limits on these bags due to the post printed process. If you are interested in a larger imprint, reach out to a sales representative to find out your options.

| Bag Size | Bag Dimensions | Imprint Size |

| Gem | 6" x 3.5" x 8.25" | 4" x 4" |

| Cub | 8" x 4.75" x 10.25" | 6" x 5" |

| Missy | 10" x 5" x 13" | 8" x 7" |

| Vogue | 16" x 6" x 13" | 10" x 6" |

| Queen | 16" x 6" x 19-1/4" | 12" x 9" |

What is Post Print ?

POST PRINT is a method of printing in which the artwork/logo is applied to the the product after the manufacturing. In the case of flexo ink printed shopping bags, this means the bags are completely assembled before being ran through a print machine which stamps the bag with a logo using a rubber plate. Gussets and handles create limits to our imprint size and location.

MILL RUN is a method of printing in which the artwork/logo is applied to the material before the product is assembled. In the case of flexo ink printed shopping bags, the paper used to build the bags are printed before the paper is cut, folded and glued to create the bag. While this generally means a higher minimum quantity, it provides the option to print on all 5 sides of the bag and sometimes even inside of the bag, depending on the manufacturer. Mill run orders offers superior flexibility in the design of your custom packaging.

If you have any questions, feel free to contact us at 800-426-5708 or [email protected]

Validate your login